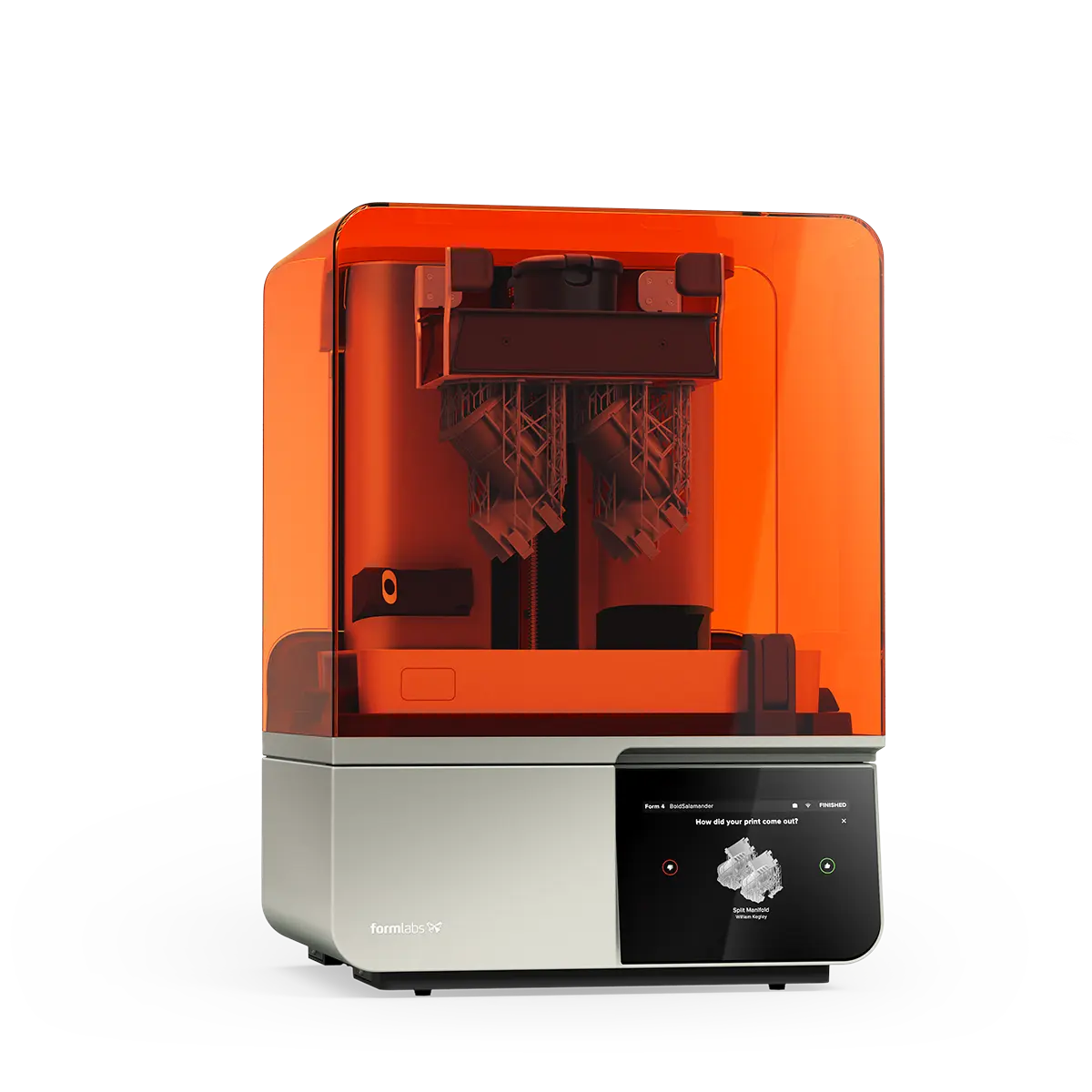

Top 5 Best Resins for Formlabs Form 4: Enhance Your 3D Printing Quality

In the ever-evolving world of 3D printing, selecting the right resin is pivotal to achieving high-quality outputs, especially when using advanced machines like the Formlabs Form 4. This powerful printer offers remarkable precision, and the choice of resin can make or break the success of your project. Whether you are creating prototypes, dental models, or intricate designs, understanding the unique attributes of each resin type can significantly enhance your printing experience. In this article, we’ll explore the top 5 best resins for Formlabs Form 4, equipping you with the knowledge to elevate your 3D printing quality.

Introduction to Formlabs Form 4 Resins

Overview of 3D Printing with Formlabs

Formlabs has cemented its place as a leader in the 3D printing industry, particularly for those utilizing stereolithography (SLA) technology. The Form 4 printer utilizes a method called resin photopolymerization, where ultraviolet (UV) light cures liquid resin layer by layer to create detailed objects. This technology allows for exceptional surface finish, unparalleled detail, and rapid prototyping capabilities. The Formlabs Form 4 is particularly known for its ability to handle a variety of resins tailored to specific applications, making it a versatile tool for professionals in design, engineering, and healthcare.

The advent of 3D printing with Formlabs has transformed numerous industries, enabling quicker product iterations and more personalized solutions. With the Form 4, users can explore an array of material properties—ranging from rigid to flexible—that cater to diverse project requirements, significantly enhancing creative freedom.

Importance of Choosing the Right Resin

When it comes to 3D printing with the Formlabs Form 4, the choice of resin holds immense importance. Different resins offer various mechanical properties, post-processing requirements, and finishing capabilities. For instance, some projects necessitate strong and durable materials, while others may require flexibility or biocompatibility. Using a resin that isn’t suited for your intended application can result in failed prints, compromised quality, or even dangerous outcomes, such as using non-sterile materials in a medical setting.

Moreover, the right resin can save time and costs associated with print failures, inefficient material usage, and excess post-processing. As such, understanding the characteristics of different resins vastly improves the likelihood of producing successful prints, making it essential for designers and manufacturers seeking to optimize their work processes.

Top 5 Resins for Formlabs Form 4

1. Rigid Resin

Rigid Resin is specifically engineered for producing solid and sturdy models, making it one of the most widely used materials for a variety of applications. Its excellent dimensional stability ensures that models retain their shapes effectively, making it ideal for parts that require precision in fit and form.

Advantages of Rigid Resin

One of the primary advantages of Rigid Resin is its outstanding strength and minimal shrinkage during the curing process. This characteristic is particularly beneficial for applications in engineering and manufacturing where dimensional accuracy is crucial. Furthermore, Rigid Resin has low post-processing requirements, allowing for faster production turnaround times. Its smooth surface finish also provides a canvas for easy painting or finishing, making it suitable for aesthetic applications.

In various study cases, Rigid Resin has been shown to not only outperform comparable materials but also demonstrate longevity under stress. Users in industries ranging from automotive to consumer goods favor Rigid Resin for prototypes that undergo functional testing due to its robust properties.

Best Applications for Rigid Resin

Rigid Resin shines in environments that demand high precision and durability. Common applications include:

- Functional prototyping for mechanical components

- Manufacturing tools and jigs

- Production of intricate designs requiring complex geometric shapes

Real-world examples, like aerospace prototypes and automotive components, leverage Rigid Resin for its ability to withstand stress while providing clear visibility into mechanical interactions.

2. Tough Resin

Tough Resin, as the name suggests, is a material designed for robust applications that require durability and resilience under impact. It offers a great balance between strength and flexibility, making it one of the best choices for both prototyping and end-use parts.

Key Features of Tough Resin

Tough Resin not only mimics the mechanical properties of injection-molded plastics but also provides exceptional resistance to impact, making it an ideal choice for applications involving dynamic loading or where part breakage is a concern. One key feature of Tough Resin is its ability to undergo slight bending without breaking, which is crucial for end-use parts that must endure repeated use or manipulation.

Indeed, Tough Resin has become a favorite among engineers and designers who prioritize both functional performance and aesthetic appeal in their prototypes. For instance, in product design and prototyping, Tough Resin enables the creation of prototypes that can be tested under real-world conditions, revealing insights into both form and function before moving to full-scale production. This capability ultimately accelerates development timelines and costs as it allows designers to make informed adjustments early in the process.

Ideal Use Cases for Tough Resin

Tough Resin is specifically engineered to withstand impact and provide reliable performance in demanding conditions. This makes it ideal for a variety of applications across different sectors. For example, engineers and product designers often utilize Tough Resin for prototyping mechanical parts due to its ability to endure stress and strain without deformation. Its strength combined with a degree of flexibility allows users to create components that simulate the properties of end-use materials, making them perfect for functional testing and fit validation. Furthermore, the ease of post-processing and its compatibility with Formlabs’ printing technology contributes to creating intricate geometries that are also durable.

Applications such as custom jigs, fixtures, and even consumer product prototypes particularly benefit from this resin. For instance, in the automotive industry, companies can prototype parts like dashboard components or housings that need to endure wear and tear while still achieving a stylish finish. Interestingly, feedback from testers in design iterations has shown a tangible improvement in real-world functionality when utilizing Tough Resin compared to traditional materials. As companies increasingly lean towards rapid prototyping, choosing Tough Resin can significantly streamline the design process, resulting in faster time-to-market for new products.

3. Dental Resin

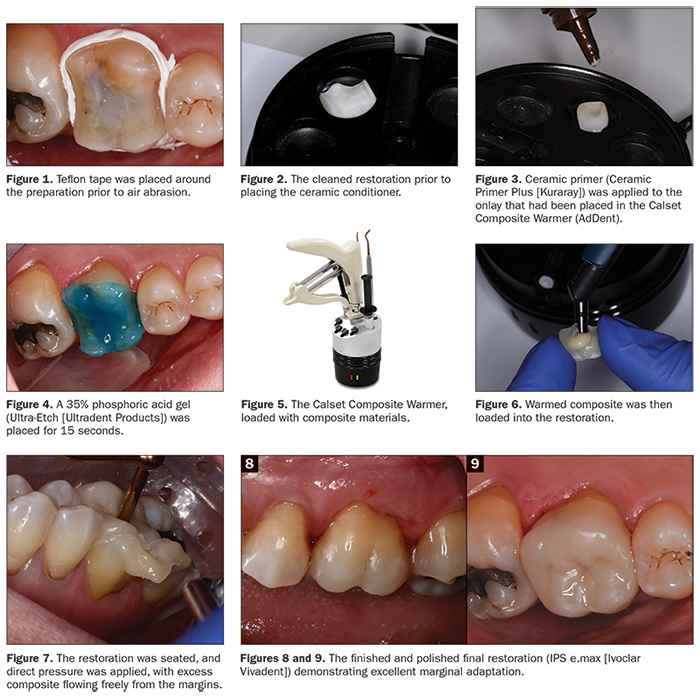

Dental Resin is fine-tuned explicitly for the dentistry field, addressing the unique requirements related to dental applications. Its formulation ensures that 3D printed dental devices offer the necessary biocompatibility and aesthetic qualities needed in dental work.

Benefits of Dental Resin for Orthodontics

One of the primary benefits of Dental Resin in orthodontics is its high level of detail and smooth finish that closely resembles how natural teeth appear. This is vital not just for aesthetic purposes but for achieving functional accuracy in orthodontic treatments. Experts emphasize the importance of precision in aligners and dental models, where even the slightest imperfection can lead to subpar results in alignment or fit. The material’s ability to replicate fine features, like grooves and ridges, lends itself to effectively capturing the nuances of dental structures, thus enhancing treatment outcomes.

Moreover, Dental Resin exhibits excellent resistance to wear, which is essential for devices that will be worn in the mouth for extended periods. By ensuring that the aligners or other dental devices remain intact and functional, practitioners can provide more reliable service to their patients. Additionally, these resins often come with a reduced risk of discoloration over time, maintaining both hygiene and aesthetic integrity.

Specific Applications in Dental Printing

In the realm of dental printing, Dental Resin finds its most notable applications in the creation of dental models, surgical guides, and aligners. Orthodontists often utilize advanced 3D printing to enhance patient treatment plans, where Digital Smile Design technology can integrate seamlessly with Dental Resin. Surgical guides prepared using 3D printed dental technology not only ensure precision during surgical procedures but also reduce operational time, as they provide clear pathways to place implants or perform extractions accurately.

Furthermore, Dental Resin can be used for custom trays for impression taking, which enhances comfort for patients while minimizing error in traditional methods. By producing these trays through 3D printing, dental practices can save time and reduce the amount of material waste typically associated with other manufacturing methods.

4. Grey Pro Resin

Grey Pro Resin has gained popularity among designers and engineers due to its exceptional printing quality and post-processing capabilities. This resin combines a fine balance of properties that make it versatile across various prototyping needs.

Characteristics and Benefits of Grey Pro Resin

One of the standout characteristics of Grey Pro Resin is its ease of post-processing. It can be painted, sanded, and polished easily, making it a favorite among those looking to create aesthetically pleasing models. The material is capable of capturing minute details, giving projects an almost professional-grade finish right off the printer. For instance, when creating miniatures or complex jewelry molds, Grey Pro’s fine details can replicate intricate designs precisely, impressing clients and stakeholders alike.

In addition to its optical properties, Grey Pro Resin has a notable strength-to-weight ratio, enabling printed parts to be lightweight yet durable. This makes it ideal for larger projects where structural integrity must not compromise design aesthetics. Users have reported using this resin effectively for components like automotive parts, consumer electronics housing, and even drone parts, all of which benefit from the resin’s resistance to wear and temperatures.

Suitable Projects for Grey Pro Resin

Grey Pro Resin is particularly suitable for applications that require a high level of detail combined with structural stability. It is often used in the creation of prototypes for consumer products, where visual appeal and functionality must meet simultaneously. For example, in the consumer electronics industry, designers prototype smartphone casings or product enclosures that require precise fit and finish—features that Grey Pro Resin delivers efficiently.

Moreover, its surface smoothness post-printing translates perfectly into applications in the gaming industry, where miniature figurines are created. These miniatures benefit not just from the clarity of features but also from the strength of the material when various paint finishes and detailing techniques are applied afterward. Thus, whether for practical or artistic applications, Grey Pro Resin proves to be a highly flexible option.

5. Castable Resin

Castable Resin is specially formulated for produce high-fidelity parts that are required for casting metals. The formulation of this resin ensures that it burns out cleanly without leaving any residue, which is a crucial characteristic for fine jewelry and other precision casting endeavors.

Overview of Castable Resin

Castable Resin allows users to create intricate designs that can later be cast in gold, silver, and other metals. This resin is tailored to meet the demands of the jewelry industry, capturing minute details that would be challenging to achieve using traditional manufacturing methods. For designers and jewelers, it transforms the process of creating wax models into a seamless transition from digital to physical pieces, enabling rapid prototyping and production.

One of the key attributes of Castable Resin is its stability at high temperatures, making it an ideal candidate for processes like lost wax casting. Manufacturers appreciate that the print quality is not compromised through the casting process, as it retains accuracy even after being subjected to high heat.

Applications in Jewelry and Casting Industries

In the world of jewelry design, Castable Resin is used to produce intricate rings, necklaces, bracelets, and pendants where detail is paramount. It allows designers to experiment with complexity that would traditionally require weeks of manual craftsmanship. For instance, a designer might create a detailed model of a vintage-style ring with delicate filigree that would be nearly impossible to achieve using traditional methods in a reasonable time frame.

Additionally, Castable Resin isn’t limited to jewelry alone. Various industries involving metal casts—such as aerospace and automotive—use this resin for prototype parts, ensuring uniformity and precision in the final product. As demand for customization and complexity in manufacturing processes increases, Castable Resin continues to fill an essential role in supporting both artistic and industrial applications, making it a valuable tool in modern production methodologies.

In conclusion, Castable Resin exemplifies how 3D printing technology can be leveraged to enhance precision and efficiency across sectors, and its impact has reshaped how manufacturers approach product development in various fields.

Comparisons of Resin Characteristics

When it comes to resin printing, especially with a high-precision standard like the Formlabs Form 4, understanding the characteristics of different resins is crucial for optimizing print quality. Resin characteristics can dramatically influence final output in terms of appearance, durability, and application suitability.

Key Metrics for Comparing Resins

Resin metrics can largely be categorized into physical properties, chemical properties, and performance indicators. The most critical metrics include:

- Viscosity: This indicates the fluidity of the resin; low-viscosity resins flow better but may take longer to cure, while high-viscosity resins can yield finer detail.

- Flexural Strength: This is crucial for functional parts, measured in MPa (megapascals). Resins with higher flexural strength are suitable for load-bearing applications.

- Tensile Strength: Similarly crucial, it measures a resin’s behavior under tension, indicating how much force the material can withstand before breaking.

- Impact Resistance: Important for parts that may experience shocks or drops; higher impact resistance translates to parts that maintain their integrity when subjected to sudden forces.

- Elongation at Break: This metric indicates how well a resin can stretch before breaking, which is essential for applications that require some level of flexibility.

- Surface Finish and Color: The appearance of the final print can impact the choice of resin significantly, especially in industries like jewelry and dental applications where aesthetic is paramount.

Understanding these metrics allows for nuanced decision-making tailored to specific project needs. For example, if a user is printing components for a prototype that will endure loading, they might prioritize resins with high flexural and tensile strengths, even if they come at a higher cost.

Cost vs. Performance Analysis

Cost versus performance is a balancing act that every 3D printing enthusiast must navigate. Quality resins tend to cost more, but they may offer greater durability and print quality, returning value over time through various means, such as reduced print failures or enhanced aesthetics.

| Resin Type | Price per Litre | Flexural Strength (MPa) | Ideal Applications |

| Tough Resin | $149 | 70 | Prototypes, Functional Parts |

| Dental Model Resin | $199 | 45 | Dental Applications |

| Clear Resin | $139 | 65 | Optical Devices, Visibility Parts |

| High-Temp Resin | $159 | 50 | Parts exposed to high temperatures |

| Flexible Resin | $169 | 30 | Gaskets, Soft Touch Requests |

As seen from the table, tougher resins tend to command a higher price, often justified by their superior performance in functional applications. This data must be considered against the specific requirements of a project. Although a cheaper resin might be tempting, it could lead to increased costs down the line if more failed prints occur, thus impacting productivity and overall quality.

Tips for Selecting the Right Resin

When selecting resin for your Form 4, it’s essential to consider various factors that contribute to ensuring that the final print meets your specifications accurately.

Factors to Consider When Choosing Resin

- Application Needs: Determine the requirements of your project. If the print will be subjected to mechanical stress, selecting a stronger resin will be crucial. Conversely, for aesthetic prints, surface finish may be the priority.

- Print Resolution: The resolution capabilities of your printer also dictate resin choice. Ensure the resin’s viscosity and properties are compatible with the printer’s resolution to avoid any misprints.

- Post-Processing Requirements: Different resins may have varied post-processing needs. Consider the additional time, effort, and materials required for cleaning and curing after printing.

- Test Samples: If uncertain, testing out small quantities of different resins can provide hands-on experience and insights into how the material performs in real-world conditions.

- Environmental Considerations: Some resins are better suited for indoor environments, while others might withstand outdoor conditions. Assessing the operational environment can guide your material choice.

Common Mistakes to Avoid

Selecting the right resin can be challenging, and several common pitfalls can lead to suboptimal results:

- Ignoring Manufacturer Guidelines: Always refer to the manufacturer’s specifications for the optimal performance of their products. Deviating from these guidelines can lead to poor adhesion, incorrect curing, or even printer damage.

- Neglecting Safety Precautions: Resin handling should always be performed with care, including wearing gloves and a mask. Many users fail to adopt essential safety precautions, which can have severe health implications.

- Overlooking Post-Curing Needs: Post-curing is crucial in resin printing. Failing to follow an adequate curing process can result in weak final products, affecting durability and surface finish quality.

- Forgetting Environmental Impact: Not considering the production environment, such as humidity and temperature, can lead to inconsistent results. Maintaining controlled conditions is to ensure resin behaviors remain predictable.

Conclusion

Summary of Top Choices

When discerning the best resins for the Formlabs Form 4, certain selections stand out: Tough Resin for functional prototypes, Dental Model Resin for precision dental applications, Clear Resin for optical clarity, High-Temp Resin for extreme conditions, and Flexible Resin for applications necessitating a softer touch. Each comes with trade-offs and advantages that cater to varying project requirements.

Final Thoughts on Resin Selection

In summary, selecting the right resin is paramount in achieving the quality, functionality, and durability of your 3D prints. By understanding key characteristics and collaborating these with project specifications, one can navigate the resin market more effectively. Avoid common mistakes, follow best practices, and conduct sufficient research before settling on a resin type. As the world of 3D printing continues to evolve, being equipped with the right knowledge will empower both novices and seasoned professionals to enhance their printing capabilities, leading to successful projects and innovations. Engage with the 3D printing community, lean on shared experiences, and keep experimenting for continual improvement in print quality.